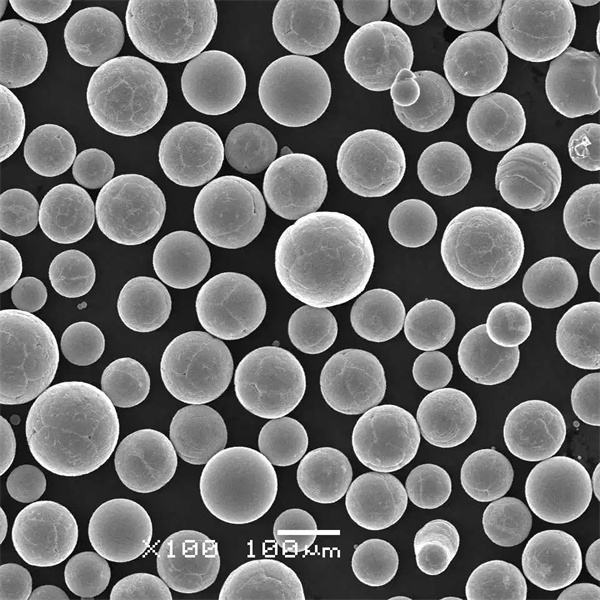

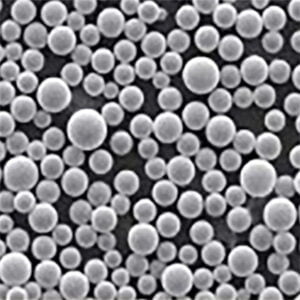

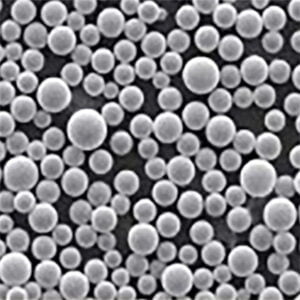

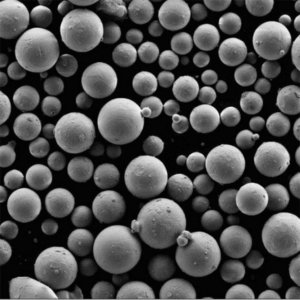

Ti45Nb-Pulver für die additive Fertigung

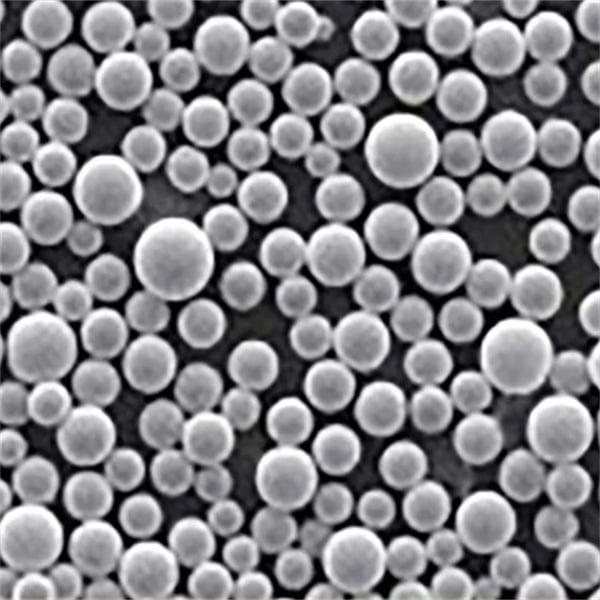

Ti45Nb-Pulver, ein Wunderwerk der Materialwissenschaft, schlägt Wellen im Bereich der additiven Fertigung.

| Metallpulver | Größe | Menge | Preis/kg |

| Ti45Nb | 15-45um | 30KG | 499 |

Haben Sie schon einmal die schiere Kraft und Effizienz eines Düsentriebwerks bestaunt, das zum Leben erwacht? Der unermüdliche Schub, der Flugzeuge über Kontinente hinweg treibt, oder die unglaubliche Energieerzeugung von industriellen Gasturbinen – all das ist einer Symphonie aus sorgfältig konstruierten Komponenten zu verdanken. Doch in diesen Wundern verbirgt sich

Einführung Haben Sie schon einmal davon geträumt, Metallgegenstände mit einer einfachen, effizienten Methode herzustellen oder zu reparieren? REP-Pulver, auch bekannt als Rapid Engineered Powder, könnten genau die Antwort sein, nach der Sie gesucht haben. Diese revolutionären Metallpulver verändern die Art und Weise, wie wir an die Metallverarbeitung herangehen, und bieten eine schnellere,

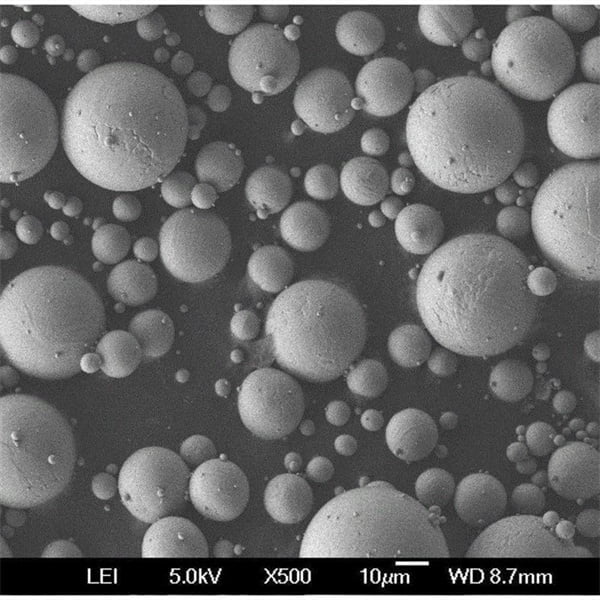

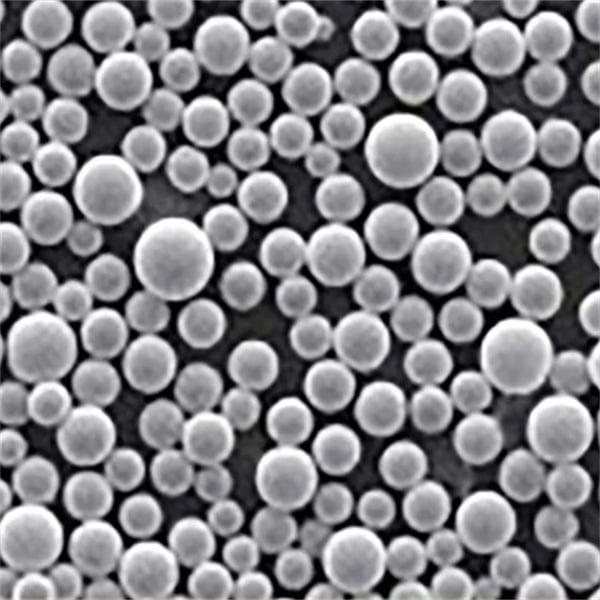

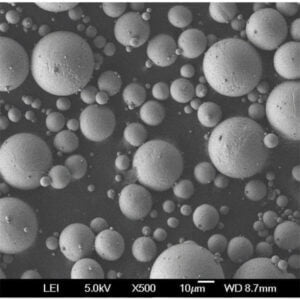

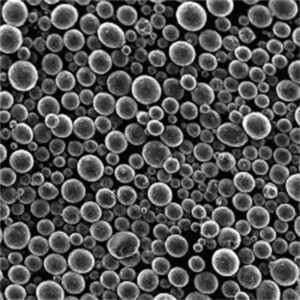

Stellen Sie sich einen Prozess vor, der einen massiven Metallstab in einen Schwarm winziger, nahezu perfekter Kugeln verwandelt – die Bausteine für hochmodernen 3D-Druck und andere fortschrittliche Anwendungen. Das ist die Magie des Rotating Electrode Process (REP), ein Wunderwerk der Physik und Materialwissenschaft, das wir gleich näher untersuchen werden.

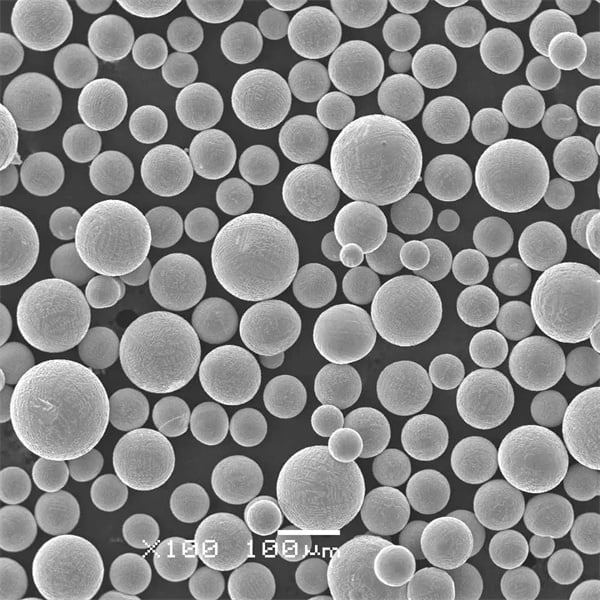

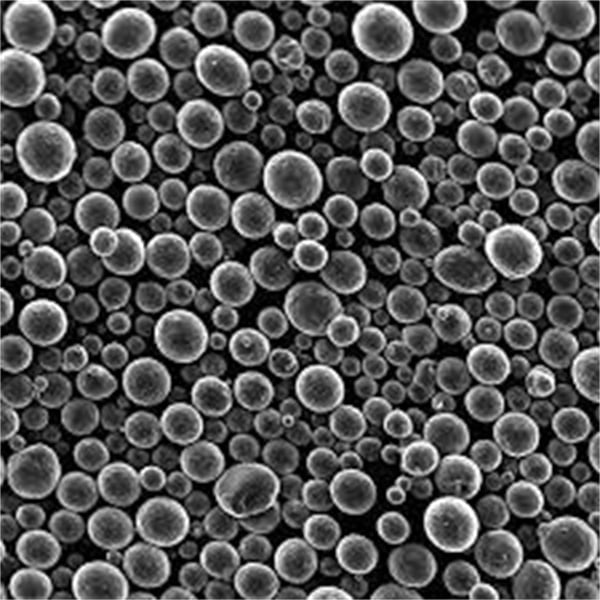

Haben Sie sich schon einmal gefragt, wie die komplizierten Teile Ihres Automotors oder die leichten Komponenten Ihres Laptops hergestellt werden? Die Antwort könnte in einem faszinierenden Prozess namens Gaszerstäubung liegen, einer Technologie, die geschmolzenes Metall in ein Meer aus winzigen, perfekt geformten Kugeln verwandelt – Metallpulver. Schnall dich an,

Helium plasma, a state of matter often referred to as the fourth state (alongside solid, liquid, and gas), might sound like something straight out of science fiction. But believe it or not, it has a surprising number of real-world applications, from medical procedures to advanced manufacturing. This article will be

Imagine a world where everything existed in giant, unusable chunks. Cars wouldn’t fit in garages, paint wouldn’ Metal components would be cumbersome and impractical. Thankfully, we have a process called atomization that breaks down materials into tiny particles, unlocking a vast array of applications. But what exactly is atomization, and

Imagine turning a scorching river of molten metal into a cloud of perfectly round, ultra-fine particles. That’s the magic of centrifugal atomization, a rapid solidification technique that’s been around for decades, silently shaping the world around us. But how exactly does it work? And what kind of incredible materials can

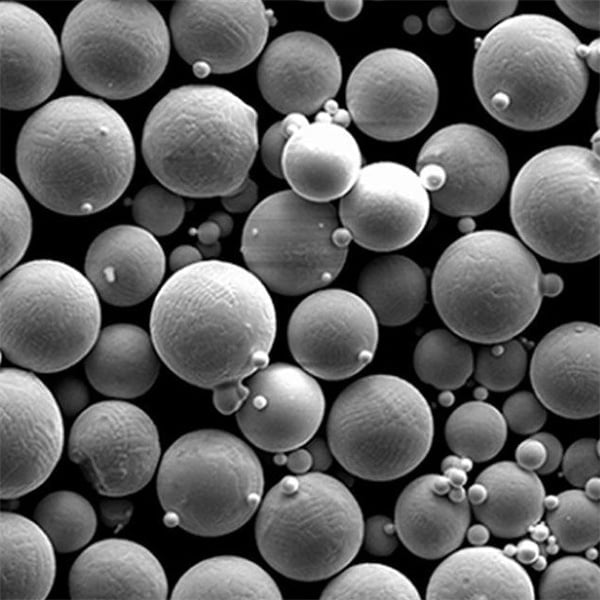

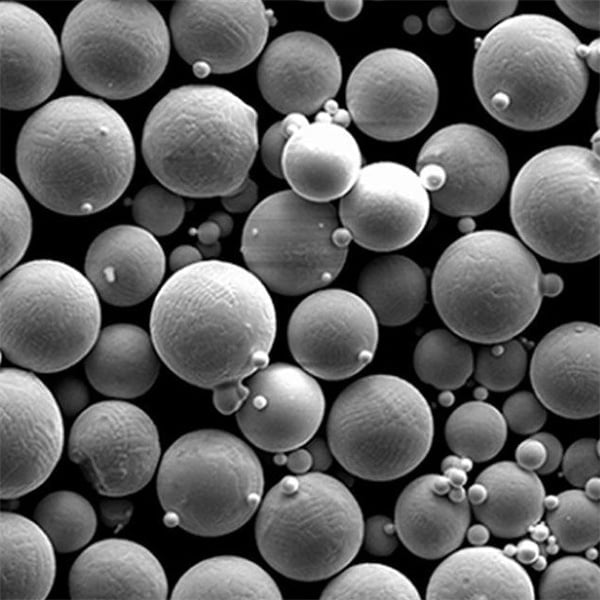

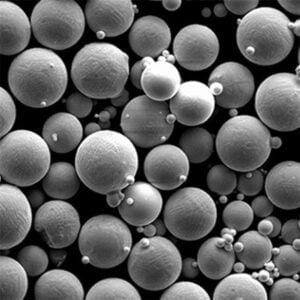

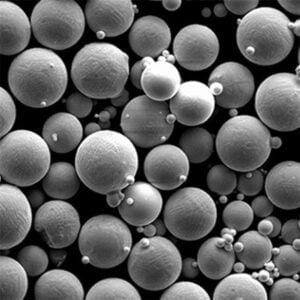

Imagine a ballet where a metal rod pirouettes at lightning speed, meeting a scorching hot plasma arc in a dazzling display. The molten metal, flung outwards by centrifugal force, cools and solidifies into tiny, near-perfect spheres. This captivating dance is the essence of the Plasma-Rotating Electrode Process (PREP), a revolutionary

The world of Powder Metallurgy (PM) is constantly evolving, with new materials emerging to push the boundaries of what’s possible. Enter AgCuTi Powder– a revolutionary metal powder composition that’s shaking things up. But what exactly is AgCuTi, and why should you care? Buckle up, because we’re about to delve into

The world of Powder Metallurgy (PM) thrives on tiny, potent ingredients. Among these champions stands BAg-8 powder, a silver-copper alloy that injects remarkable properties into PM parts. Let’s delve into the fascinating world of BAg-8, exploring its composition, applications, and why it’s a PM powerhouse. BAg-8 Powder: Composition and Characteristics

Have you ever marveled at the sheer power and efficiency of a jet engine roaring to life? The relentless thrust that propels airplanes across continents or the incredible energy generation of industrial gas turbines – it’s all thanks to a symphony of meticulously engineered components. But hidden within these marvels of machinery lies a secret

Introduction Have you ever dreamt of building or repairing metal objects with a simple, efficient method? Well, REP powders, also known as Rapid Engineered Powder, might just be the answer you’ve been searching for. These revolutionary metal powders are transforming the way we approach metal fabrication, offering a faster, more precise, and often more cost-effective

Imagine a process that transforms a solid metal rod into a swarm of tiny, near-perfect spheres – the building blocks for cutting-edge 3D printing and other advanced applications. This is the magic of the Rotating Electrode Process (REP), a marvel of physics and material science that we’re about to delve into. Process Principle of the

Have you ever wondered how those intricate parts in your car engine or the lightweight components in your laptop are made? The answer might lie in a fascinating process called gas atomization, a technology that transforms molten metal into a sea of tiny, perfectly-shaped spheres – metal powders. Buckle up, because we’re diving deep into

Helium plasma, a state of matter often referred to as the fourth state (alongside solid, liquid, and gas), might sound like something straight out of science fiction. But believe it or not, it has a surprising number of real-world applications, from medical procedures to advanced manufacturing. This article will be your one-stop shop for understanding

Imagine a world where everything existed in giant, unusable chunks. Cars wouldn’t fit in garages, paint wouldn’ Metal components would be cumbersome and impractical. Thankfully, we have a process called atomization that breaks down materials into tiny particles, unlocking a vast array of applications. But what exactly is atomization, and how does it work? Buckle

Imagine turning a scorching river of molten metal into a cloud of perfectly round, ultra-fine particles. That’s the magic of centrifugal atomization, a rapid solidification technique that’s been around for decades, silently shaping the world around us. But how exactly does it work? And what kind of incredible materials can it produce? Buckle up, because

Imagine a ballet where a metal rod pirouettes at lightning speed, meeting a scorching hot plasma arc in a dazzling display. The molten metal, flung outwards by centrifugal force, cools and solidifies into tiny, near-perfect spheres. This captivating dance is the essence of the Plasma-Rotating Electrode Process (PREP), a revolutionary technology for creating high-performance metal

The world of Powder Metallurgy (PM) is constantly evolving, with new materials emerging to push the boundaries of what’s possible. Enter AgCuTi Powder– a revolutionary metal powder composition that’s shaking things up. But what exactly is AgCuTi, and why should you care? Buckle up, because we’re about to delve into the fascinating world of this

The world of Powder Metallurgy (PM) thrives on tiny, potent ingredients. Among these champions stands BAg-8 powder, a silver-copper alloy that injects remarkable properties into PM parts. Let’s delve into the fascinating world of BAg-8, exploring its composition, applications, and why it’s a PM powerhouse. BAg-8 Powder: Composition and Characteristics BAg-8 Powder, also known as

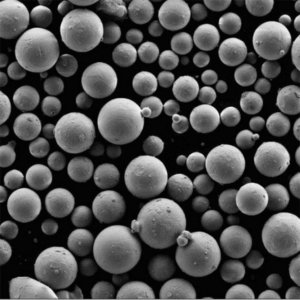

Ti45Nb-Pulver, ein Wunderwerk der Materialwissenschaft, schlägt Wellen im Bereich der additiven Fertigung.

| Metallpulver | Größe | Menge | Preis/kg |

| Ti45Nb | 15-45um | 30KG | 499 |

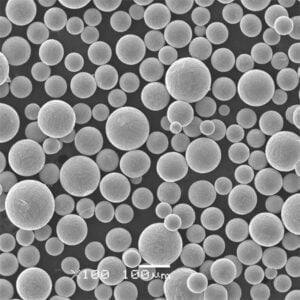

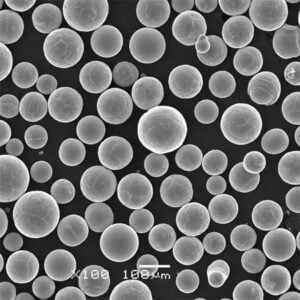

Spherical Stainless Steel Powder 15-5PH gehört zur angesehenen Familie der ausscheidungshärtenden (PH) Edelstähle. Wie der Name schon sagt, hat das Pulver eine kugelförmige Form, die für einen reibungslosen Fluss und eine außergewöhnliche Leistung in additiven Fertigungsverfahren wie Laserstrahlschmelzen (LBM) und Elektronenstrahlschmelzen (EBM) entscheidend ist.

410L-Edelstahlpulver ist eine Art von Metallpulver, das für seine gute Ausgewogenheit von Festigkeit, Härte und angemessener Korrosionsbeständigkeit bekannt ist. Es wird häufig in additiven Fertigungsverfahren wie dem Metallspritzguss (MIM) verwendet, um komplexe und endkonturnahe Bauteile herzustellen.

Haben Sie Fragen? Senden Sie uns jetzt eine Nachricht! Wir werden Ihre Anfrage mit einem ganzen Team nach Erhalt Ihrer Nachricht bearbeiten.

Metallpulver für 3D-Druck und additive Fertigung