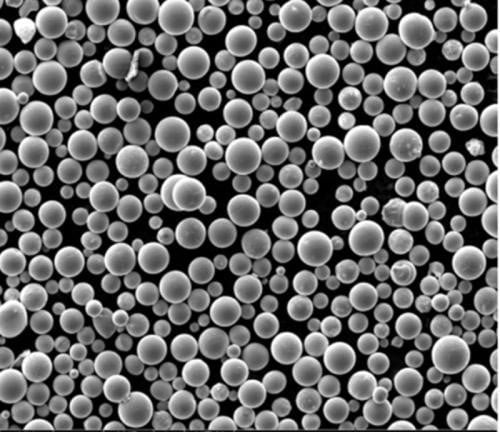

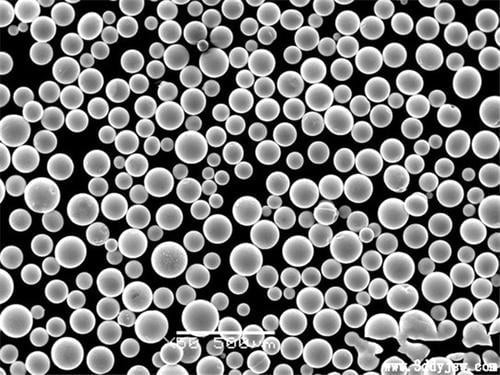

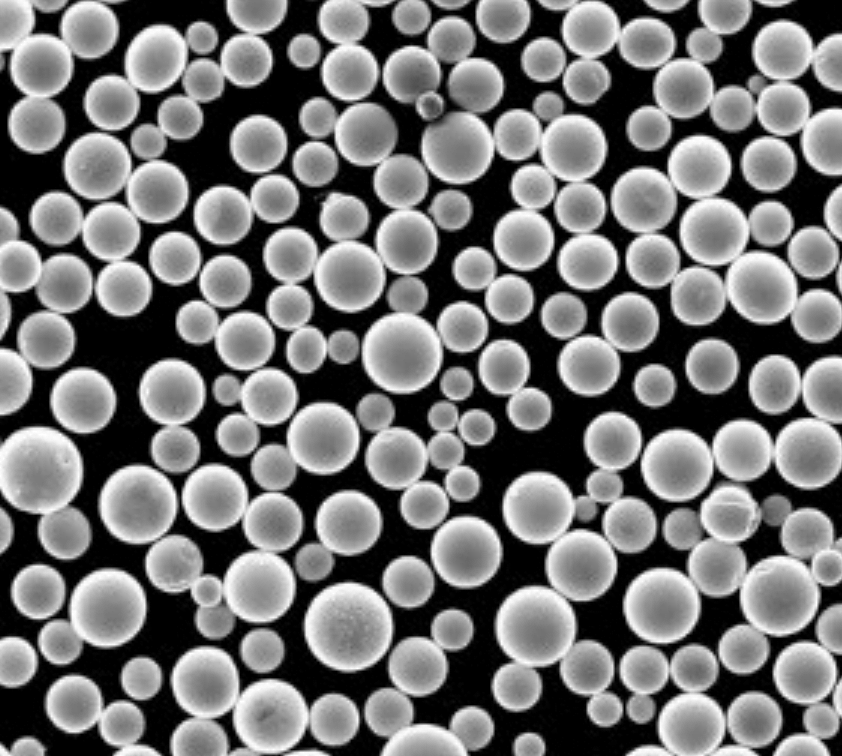

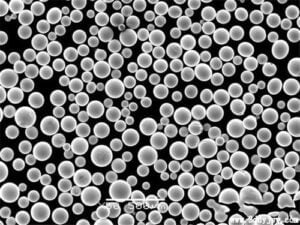

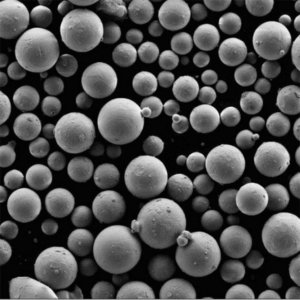

Ti45Nb-Pulver für die additive Fertigung

Ti45Nb-Pulver, ein Wunderwerk der Materialwissenschaft, schlägt Wellen im Bereich der additiven Fertigung.

| Metallpulver | Größe | Menge | Preis/kg |

| Ti45Nb | 15-45um | 30KG | 499 |

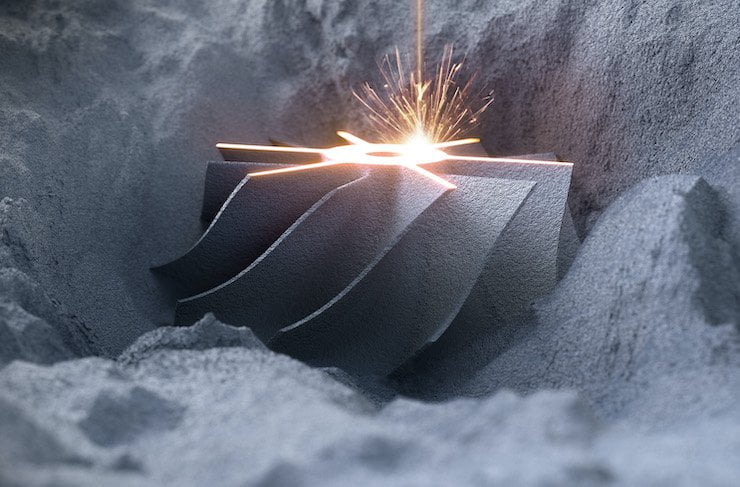

Additive manufacturing (AM), also known as 3D printing, has revolutionized the way we create complex metal components. But within this exciting realm, two titans stand out: Selective Laser Melting (SLM) and Electron Beam Melting (EBM). Both utilize a powder bed fusion technique, but their internal workings reveal fascinating distinctions. Let’s

Electron Beam Melting (EBM) has emerged as a revolutionary force in the world of 3D printing, allowing for the creation of complex, high-performance metal parts. But what exactly is EBM, and how does it work? This comprehensive guide delves into the intricacies of EBM technology, exploring its core principles, the

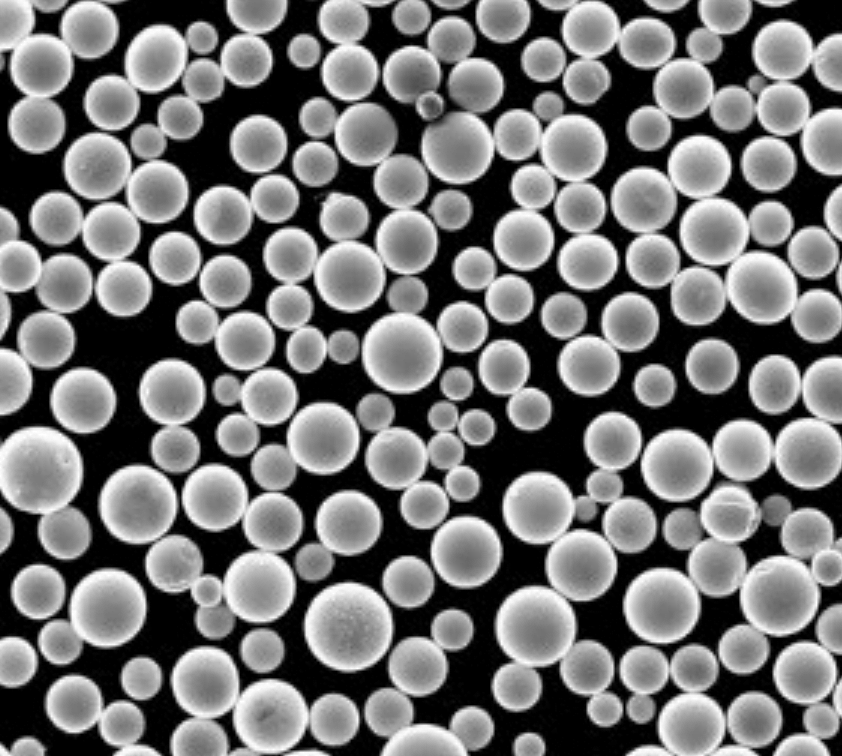

Imagine crafting intricate metal parts layer by layer, with unparalleled precision and complexity. That’s the magic of Electron Beam Melting (EBM) technology, a revolutionary 3D printing process that’s transforming manufacturing. But at the heart of this innovation lies a crucial ingredient: metal powders. Not just any metal powder will do,

Imagine a world where mold manufacturing transcends traditional limitations. A world where intricate designs and complex cooling channels are no longer obstacles, but opportunities. This world is becoming a reality thanks to Electron Beam Melting (EBM) technology, a revolutionary additive manufacturing process shaking the foundations of the mold-making industry. EBM

Imagine a world where medical devices are no longer one-size-fits-all, but meticulously crafted to perfectly match the unique needs of each patient. This vision is rapidly becoming reality thanks to Electron Beam Melting (EBM) technology, a revolutionary additive manufacturing process shaking the foundations of the medical device industry. EBM utilizes

The aerospace industry thrives on innovation. Every gram shaved off an aircraft translates to increased fuel efficiency and longer flight ranges. Every component that boasts superior strength-to-weight ratio pushes the boundaries of what’s possible. Enter Electron Beam Melting (EBM) technology, a revolutionary additive manufacturing (AM) process that’s rapidly transforming how

Electron Beam Melting (EBM) has revolutionized additive manufacturing (AM), enabling the creation of complex, high-performance metal parts. But like any technology, EBM comes with its own set of challenges. Let’s delve into the limitations of EBM, exploring its impact on material selection, surface quality, and overall process efficiency. The Equipment

Electron Beam Melting (EBM) has emerged as a revolutionary force in the world of additive manufacturing (AM), also known as 3D printing. This captivating technology utilizes a focused electron beam to meticulously melt and fuse metal powders layer by layer, building intricate and high-performance components. But what truly sets EBM

Electron Beam Melting (EBM) is a revolutionary 3D printing technology that’s rapidly transforming the manufacturing landscape. Imagine building complex metal parts layer by layer using a focused electron beam – that’s the essence of EBM! But have you ever wondered what goes on behind the scenes of this high-tech process?

Imagine a world where intricate medical devices, perfectly tailored to individual patients, are manufactured on-demand. This isn’t science fiction; it’s the reality of Selective Laser Melting (SLM), a revolutionary 3D printing technology transforming the future of healthcare. SLM, also known as Laser Powder Bed Fusion (LPBF), utilizes a high-powered laser

Additive manufacturing (AM), also known as 3D printing, has revolutionized the way we create complex metal components. But within this exciting realm, two titans stand out: Selective Laser Melting (SLM) and Electron Beam Melting (EBM). Both utilize a powder bed fusion technique, but their internal workings reveal fascinating distinctions. Let’s delve into the intricate dance

Electron Beam Melting (EBM) has emerged as a revolutionary force in the world of 3D printing, allowing for the creation of complex, high-performance metal parts. But what exactly is EBM, and how does it work? This comprehensive guide delves into the intricacies of EBM technology, exploring its core principles, the fascinating world of EBM metal

Imagine crafting intricate metal parts layer by layer, with unparalleled precision and complexity. That’s the magic of Electron Beam Melting (EBM) technology, a revolutionary 3D printing process that’s transforming manufacturing. But at the heart of this innovation lies a crucial ingredient: metal powders. Not just any metal powder will do, mind you. EBM demands powders

Imagine a world where mold manufacturing transcends traditional limitations. A world where intricate designs and complex cooling channels are no longer obstacles, but opportunities. This world is becoming a reality thanks to Electron Beam Melting (EBM) technology, a revolutionary additive manufacturing process shaking the foundations of the mold-making industry. EBM technology utilizes a high-powered electron

Imagine a world where medical devices are no longer one-size-fits-all, but meticulously crafted to perfectly match the unique needs of each patient. This vision is rapidly becoming reality thanks to Electron Beam Melting (EBM) technology, a revolutionary additive manufacturing process shaking the foundations of the medical device industry. EBM utilizes a highly focused electron beam

The aerospace industry thrives on innovation. Every gram shaved off an aircraft translates to increased fuel efficiency and longer flight ranges. Every component that boasts superior strength-to-weight ratio pushes the boundaries of what’s possible. Enter Electron Beam Melting (EBM) technology, a revolutionary additive manufacturing (AM) process that’s rapidly transforming how we design and manufacture critical

Electron Beam Melting (EBM) has revolutionized additive manufacturing (AM), enabling the creation of complex, high-performance metal parts. But like any technology, EBM comes with its own set of challenges. Let’s delve into the limitations of EBM, exploring its impact on material selection, surface quality, and overall process efficiency. The Equipment Cost of EBM Process is

Electron Beam Melting (EBM) has emerged as a revolutionary force in the world of additive manufacturing (AM), also known as 3D printing. This captivating technology utilizes a focused electron beam to meticulously melt and fuse metal powders layer by layer, building intricate and high-performance components. But what truly sets EBM apart? Buckle up, because we’re

Electron Beam Melting (EBM) is a revolutionary 3D printing technology that’s rapidly transforming the manufacturing landscape. Imagine building complex metal parts layer by layer using a focused electron beam – that’s the essence of EBM! But have you ever wondered what goes on behind the scenes of this high-tech process? Buckle up, because we’re about

Imagine a world where intricate medical devices, perfectly tailored to individual patients, are manufactured on-demand. This isn’t science fiction; it’s the reality of Selective Laser Melting (SLM), a revolutionary 3D printing technology transforming the future of healthcare. SLM, also known as Laser Powder Bed Fusion (LPBF), utilizes a high-powered laser to meticulously melt and fuse

Ti45Nb-Pulver, ein Wunderwerk der Materialwissenschaft, schlägt Wellen im Bereich der additiven Fertigung.

| Metallpulver | Größe | Menge | Preis/kg |

| Ti45Nb | 15-45um | 30KG | 499 |

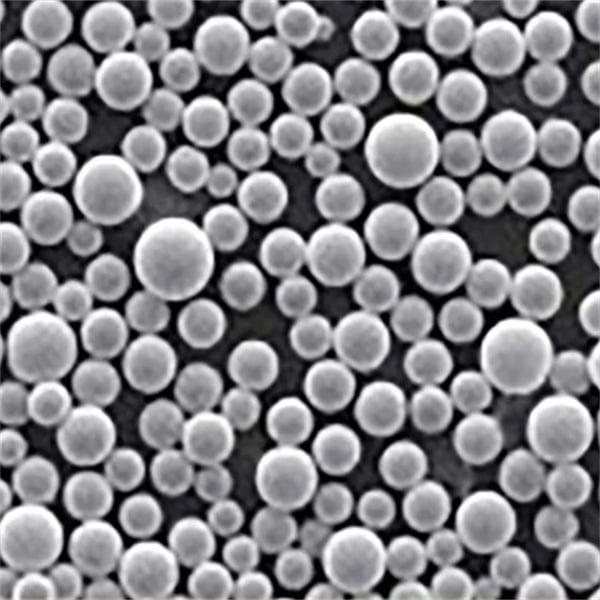

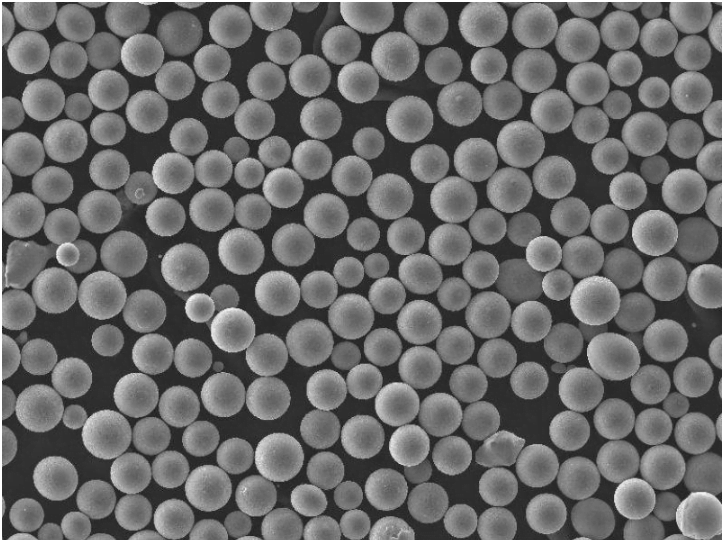

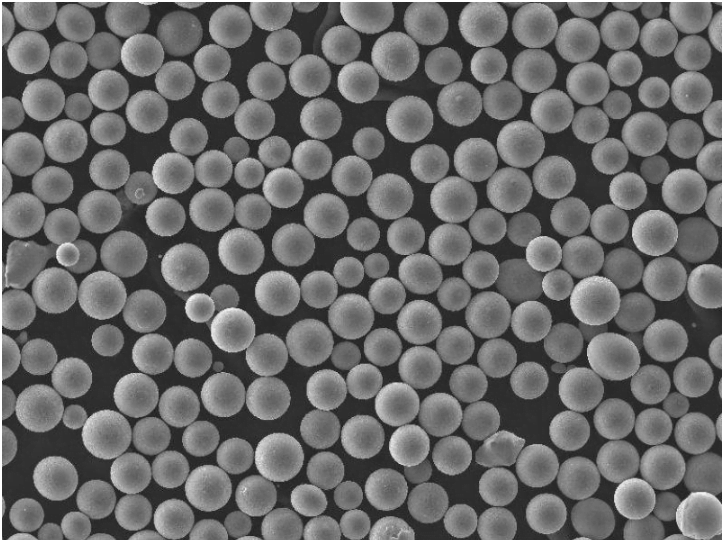

Spherical Stainless Steel Powder 15-5PH gehört zur angesehenen Familie der ausscheidungshärtenden (PH) Edelstähle. Wie der Name schon sagt, hat das Pulver eine kugelförmige Form, die für einen reibungslosen Fluss und eine außergewöhnliche Leistung in additiven Fertigungsverfahren wie Laserstrahlschmelzen (LBM) und Elektronenstrahlschmelzen (EBM) entscheidend ist.

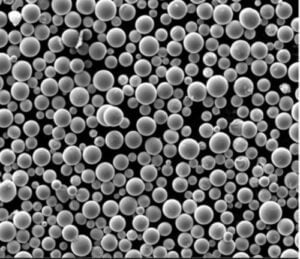

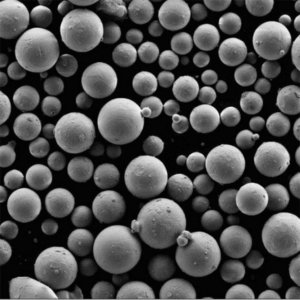

410L-Edelstahlpulver ist eine Art von Metallpulver, das für seine gute Ausgewogenheit von Festigkeit, Härte und angemessener Korrosionsbeständigkeit bekannt ist. Es wird häufig in additiven Fertigungsverfahren wie dem Metallspritzguss (MIM) verwendet, um komplexe und endkonturnahe Bauteile herzustellen.

Haben Sie Fragen? Senden Sie uns jetzt eine Nachricht! Wir werden Ihre Anfrage mit einem ganzen Team nach Erhalt Ihrer Nachricht bearbeiten.

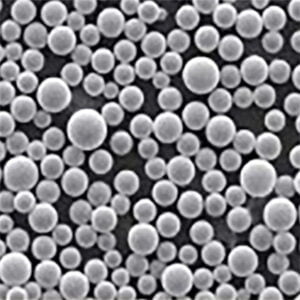

Metallpulver für 3D-Druck und additive Fertigung