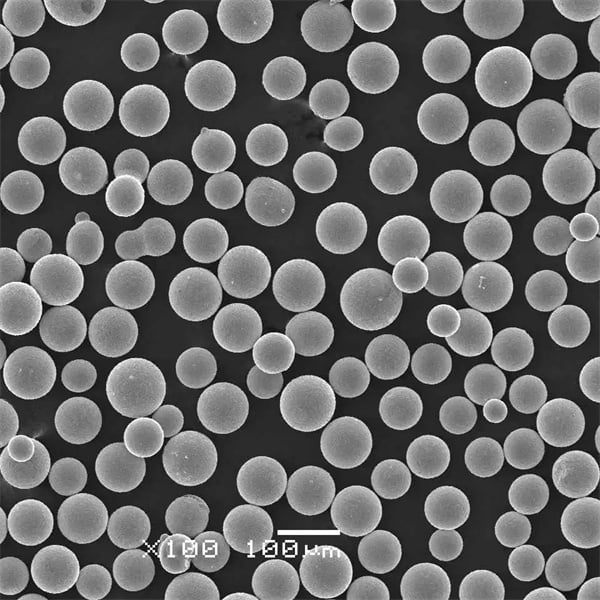

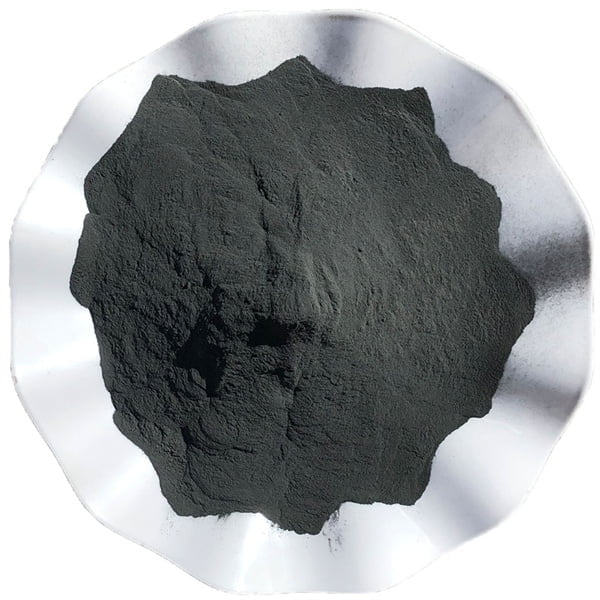

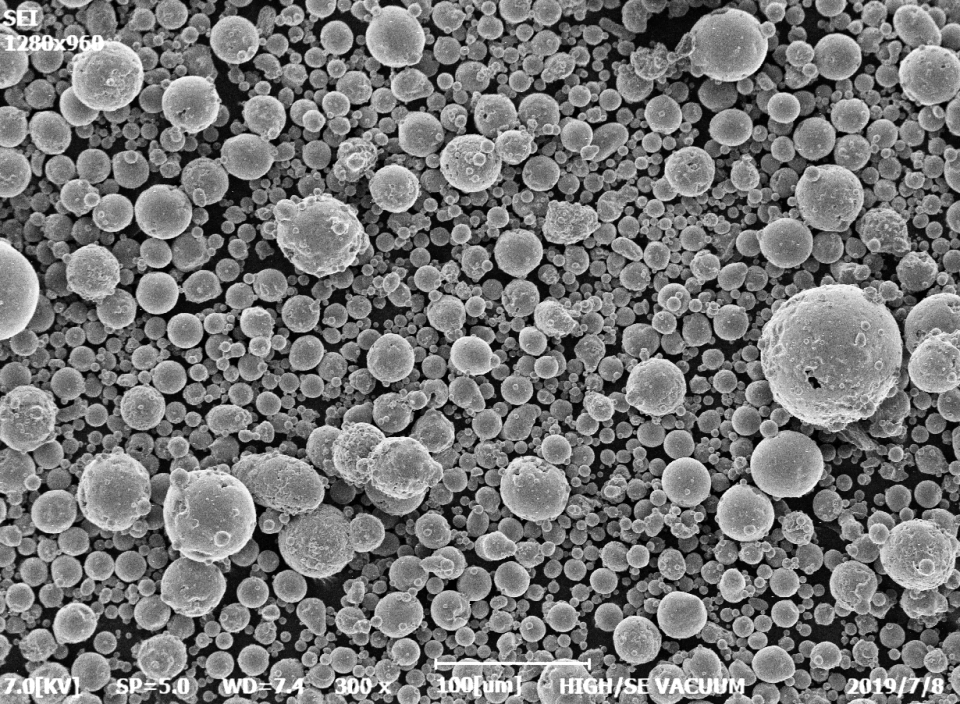

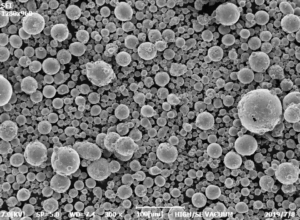

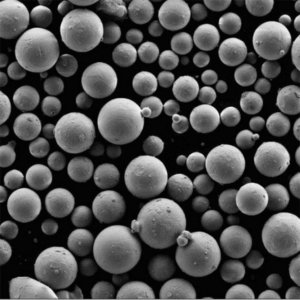

Ti45Nb-Pulver für die additive Fertigung

Ti45Nb-Pulver, ein Wunderwerk der Materialwissenschaft, schlägt Wellen im Bereich der additiven Fertigung.

| Metallpulver | Größe | Menge | Preis/kg |

| Ti45Nb | 15-45um | 30KG | 499 |

Have you ever wondered how those stunning visuals come to life on your projector screen or how your smartphone displays intricate details with such clarity? The magic behind these feats of modern technology lies in a remarkable innovation called Digital Light Processing, or DLP. DLP is a cutting-edge projection technology

Imagine a world where intricate designs materialize from a vat of liquid resin, layer by painstaking layer, with breathtaking detail and unparalleled smoothness. This isn’t science fiction; it’s the revolutionary realm of Stereolithography (SLA) 3D printing technology. But what exactly is SLA, and how does it work its magic? Buckle

Imagine a world where you can transform digital dreams into tangible objects, layer by layer. This isn’t science fiction; it’s the reality of Fused Deposition Modeling (FDM) 3D printing, a revolutionary technology that’s democratizing manufacturing and igniting creativity across industries. But how exactly does FDM printing work? What are its

Additive manufacturing, also known as 3D printing, has transformed the way we design and produce objects. Imagine building something layer by layer, like constructing a miniature brick castle one tiny piece at a time. That’s the essence of 3D printing, where a digital blueprint is translated into a physical object

Imagine a world where intricate jewelry designs transform from concept to dazzling reality in a matter of hours, not weeks. This isn’t science fiction; it’s the exciting reality of 3D printing technology in the jewelry design industry. For centuries, jewelry creation has relied on traditional methods like hand-carving and mold-making.

Imagine crafting intricate jewelry designs that were once impossible with traditional techniques. Imagine rings with delicate lacework details, pendants with impossible geometric shapes, and earrings that defy gravity. This is the revolutionary world of 3D printed jewelry, where metal powders transform digital concepts into stunning, tangible pieces. But what kind

Imagine a world where intricate jewelry designs, once confined to the realm of imagination, spring into reality with a whirring printer. This is no longer a scene from a sci-fi movie; it’s the exciting present of the jewelry industry, thanks to the transformative power of Additive Manufacturing. Additive manufacturing technology,

Imagine crafting intricate objects, from delicate jewelry to sturdy machine parts, not by carving or welding, but by building them layer by layer with a laser beam and a vat of fine metallic dust. This isn’t science fiction; it’s the reality of 3D printing metal powder, a revolutionary technology transforming

Imagine a world where manufacturing creates less waste and precious resources are used more efficiently. In the realm of 3D printing, this vision is becoming a reality thanks to advancements in recycling and utilizing metal powder. This revolutionary approach isn’t just about saving money; it’s about minimizing environmental impact and

Imagine a world where complex metal parts materialize from a bed of shimmering dust, revolutionizing manufacturing. This is the alluring promise of 3D printing with metal powder. But like any powerful technology, it waltzes with a complex environmental partner. Let’s delve into the intricate dance between 3D printing metal powder

Have you ever wondered how those stunning visuals come to life on your projector screen or how your smartphone displays intricate details with such clarity? The magic behind these feats of modern technology lies in a remarkable innovation called Digital Light Processing, or DLP. DLP is a cutting-edge projection technology that utilizes millions of microscopic

Imagine a world where intricate designs materialize from a vat of liquid resin, layer by painstaking layer, with breathtaking detail and unparalleled smoothness. This isn’t science fiction; it’s the revolutionary realm of Stereolithography (SLA) 3D printing technology. But what exactly is SLA, and how does it work its magic? Buckle up, because we’re about to

Imagine a world where you can transform digital dreams into tangible objects, layer by layer. This isn’t science fiction; it’s the reality of Fused Deposition Modeling (FDM) 3D printing, a revolutionary technology that’s democratizing manufacturing and igniting creativity across industries. But how exactly does FDM printing work? What are its strengths and limitations? And how

Additive manufacturing, also known as 3D printing, has transformed the way we design and produce objects. Imagine building something layer by layer, like constructing a miniature brick castle one tiny piece at a time. That’s the essence of 3D printing, where a digital blueprint is translated into a physical object through the meticulous stacking of

Imagine a world where intricate jewelry designs transform from concept to dazzling reality in a matter of hours, not weeks. This isn’t science fiction; it’s the exciting reality of 3D printing technology in the jewelry design industry. For centuries, jewelry creation has relied on traditional methods like hand-carving and mold-making. While these techniques produce stunning

Imagine crafting intricate jewelry designs that were once impossible with traditional techniques. Imagine rings with delicate lacework details, pendants with impossible geometric shapes, and earrings that defy gravity. This is the revolutionary world of 3D printed jewelry, where metal powders transform digital concepts into stunning, tangible pieces. But what kind of metal magic are we

Imagine a world where intricate jewelry designs, once confined to the realm of imagination, spring into reality with a whirring printer. This is no longer a scene from a sci-fi movie; it’s the exciting present of the jewelry industry, thanks to the transformative power of Additive Manufacturing. Additive manufacturing technology, also known as Additive Manufacturing,

Imagine crafting intricate objects, from delicate jewelry to sturdy machine parts, not by carving or welding, but by building them layer by layer with a laser beam and a vat of fine metallic dust. This isn’t science fiction; it’s the reality of 3D printing metal powder, a revolutionary technology transforming manufacturing across industries. Traditional Jewelry

Imagine a world where manufacturing creates less waste and precious resources are used more efficiently. In the realm of 3D printing, this vision is becoming a reality thanks to advancements in recycling and utilizing metal powder. This revolutionary approach isn’t just about saving money; it’s about minimizing environmental impact and pushing the boundaries of sustainable

Imagine a world where complex metal parts materialize from a bed of shimmering dust, revolutionizing manufacturing. This is the alluring promise of 3D printing with metal powder. But like any powerful technology, it waltzes with a complex environmental partner. Let’s delve into the intricate dance between 3D printing metal powder and our planet, exploring both

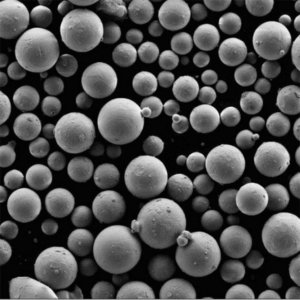

Ti45Nb-Pulver, ein Wunderwerk der Materialwissenschaft, schlägt Wellen im Bereich der additiven Fertigung.

| Metallpulver | Größe | Menge | Preis/kg |

| Ti45Nb | 15-45um | 30KG | 499 |

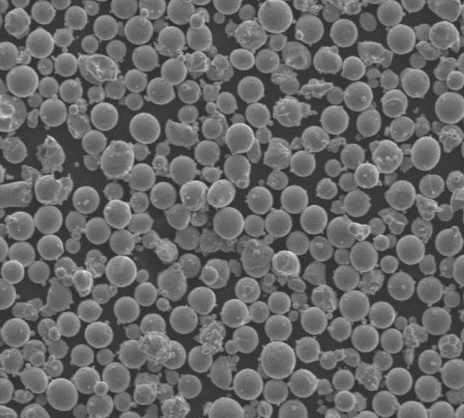

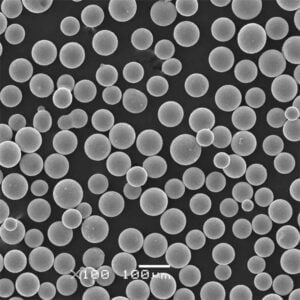

Spherical Stainless Steel Powder 15-5PH gehört zur angesehenen Familie der ausscheidungshärtenden (PH) Edelstähle. Wie der Name schon sagt, hat das Pulver eine kugelförmige Form, die für einen reibungslosen Fluss und eine außergewöhnliche Leistung in additiven Fertigungsverfahren wie Laserstrahlschmelzen (LBM) und Elektronenstrahlschmelzen (EBM) entscheidend ist.

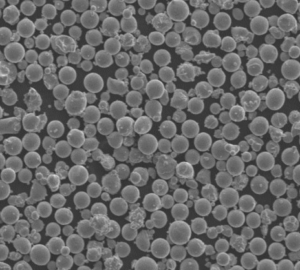

410L-Edelstahlpulver ist eine Art von Metallpulver, das für seine gute Ausgewogenheit von Festigkeit, Härte und angemessener Korrosionsbeständigkeit bekannt ist. Es wird häufig in additiven Fertigungsverfahren wie dem Metallspritzguss (MIM) verwendet, um komplexe und endkonturnahe Bauteile herzustellen.

Haben Sie Fragen? Senden Sie uns jetzt eine Nachricht! Wir werden Ihre Anfrage mit einem ganzen Team nach Erhalt Ihrer Nachricht bearbeiten.

Metallpulver für 3D-Druck und additive Fertigung